Connecting the system elements is performed by means of socket welding (thermal polyfusion) by means of electric welders. This welding method creates uniform connections and guarantees exceptional tightness and mechanic durability of the installation.

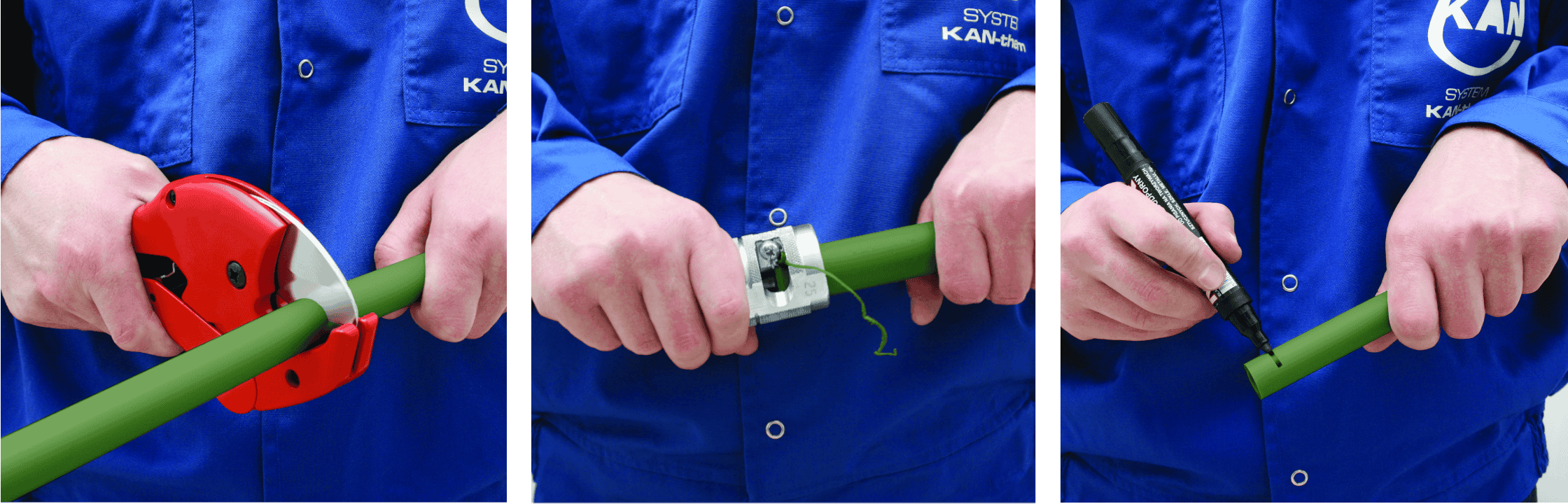

The selected pipe should be cut perpendicularly to the axis to the required length by means of plastic pipe cutters. It is not allowed to use other tools or cutters which are faulty (blunt or chipped).

Put the sliding sleeve onto the pipe. Symmetrical construction makes double-sided assembly possible.

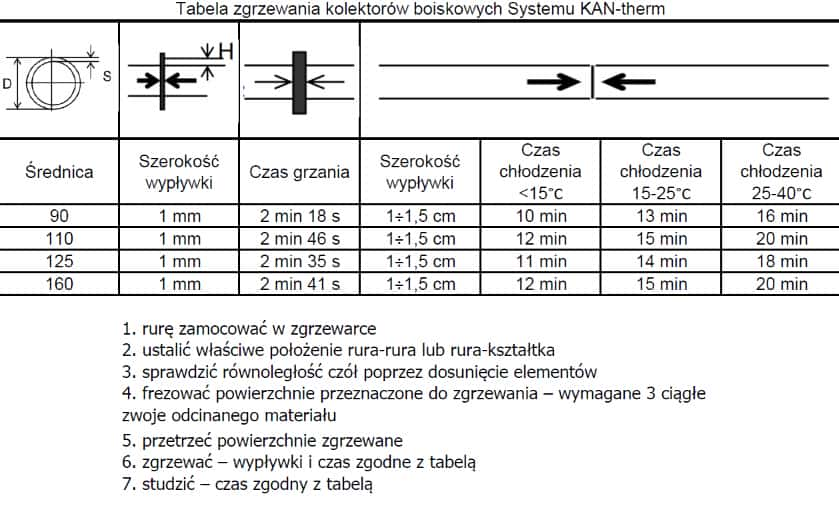

Pipelines of diameters of 90 - 200mm can also be butt-welded (without fittings).

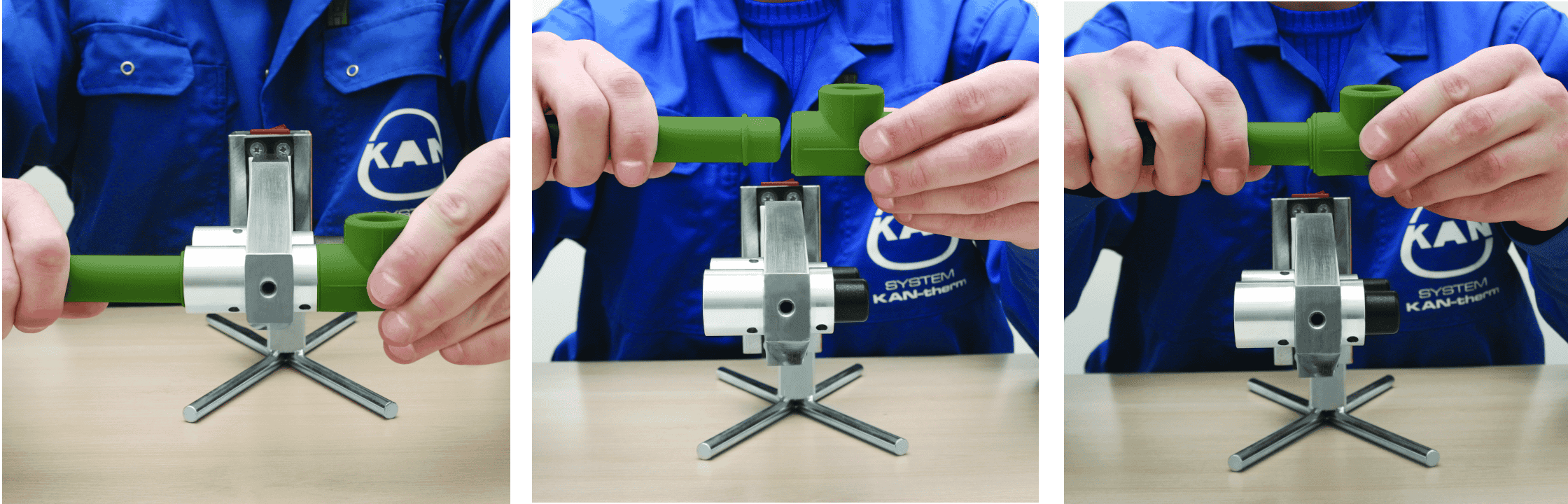

- Stripping the external part of the pipe to the size of the opening of the fitting, for example

- Cleaning the surface of stripped pipes with alcohol

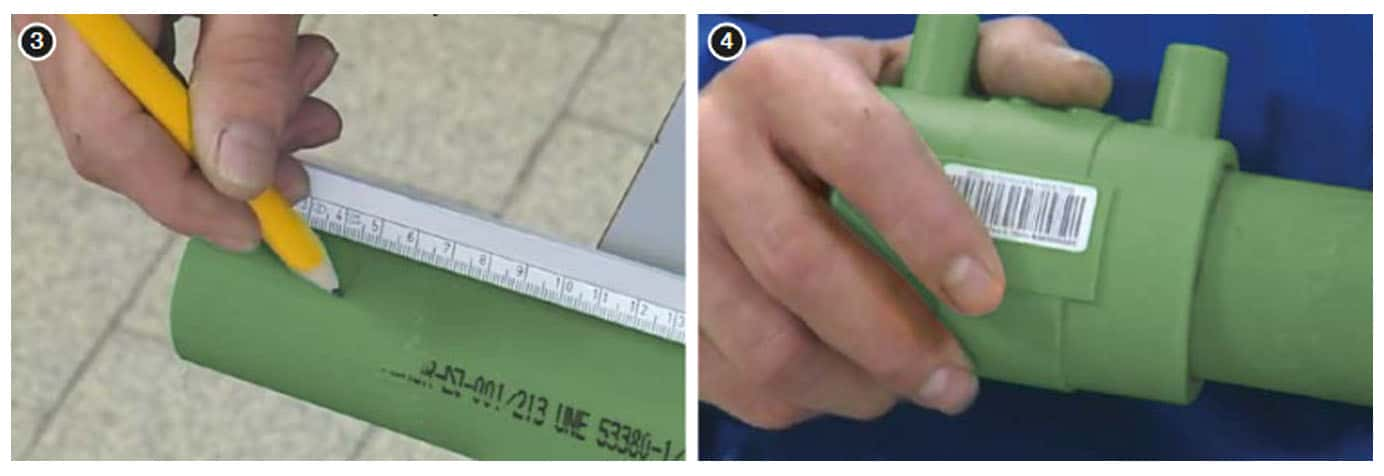

3. Marking the insertion depth

4. Insert the pipe into the connector

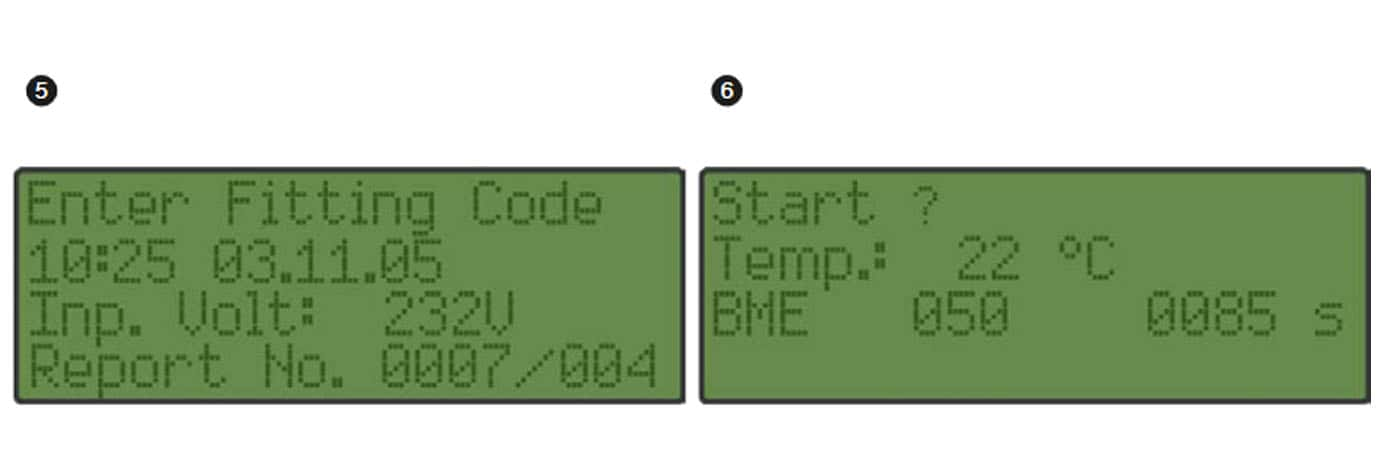

5. Programming the welding machine with the laser scanner (the welding machine adjusts parameters automatically)

6. Starting the welding process - the pipe must not be rotated, bent or pulled during the process.

12615 Tallinn

e-mail: [email protected]

Küpsiste seaded

Kasutame küpsiseid, et pakkuda erinevaid teenuseid, neid jätkuvalt täiustada, kuvada meie veebilehel teie huvidele vastavaid reklaame ning pakkuda sotsiaalmeedia funktsioone. Mõned küpsised on vajalikud selleks, et meie veebileht töötaks õigesti ning et saaksite selle funktsioone kasutada. Teie nõusolekul kasutame ka analüüsiküpsiseid, et oma veebilehte täiustada ning turundusküpsiseid, et kuvada oma veebilehel reklaame ja muud sisu. Lähemalt küpsistest ja sellest, kuidas neid kasutame.

Kui klõpsate „Nõustun kõigiga“, nõustute kõigi küpsiste kasutamisega. Kui klõpsate „Kohanda küpsiste seadeid“, saate valida, milliste küpsistega nõustute. Saate igal ajal oma küpsisteseadeid muuta või oma nõusoleku tagasi võtta.

Küpsiste seaded

See tööriist aitab valida ja välja lülitada sellel veebilehel kasutatavaid märgendeid/jälgijaid/analüüsiriistu.

-

Vajalikud teenused

Need tehnoloogiad on vajalikud veebilehe põhifunktsioonide tööks.

Clickmeeting

Freshmail

YouTube Video

GrafiteCMS

e-värbaja

-

Turundusteenused

Neid tehnoloogiaid kasutavad reklaamijad, et kuvada reklaame, mis võivad teid huvitada.

Facebook Pixel

Facebook Social Plugins

-

Analüüsiteenused

Need tehnoloogiad võimaldavad meil analüüsida veebilehe kasutamist, et mõõta ja täiustada selle toimimist.

Google Tag Manager

Google Ads

Google Ads Conversion Tracking

SmartLook

AddThis

Yandex Metrica

Google Maps

Google Analytics

Isikuandmete esitamine on vabatahtlik, kuigi vajalik teie konto ja sellega seotud funktsioonide nõuetekohaseks tööks. Kasutaja õigusi, sealhulgas õigus tutvuda andmete sisuga, andmeid parandada, kustutada, nende töötlemist ja teisaldatavust piirata, vaidlustada, nõusolek igal ajal tagasi võtta, ilma et see mõjutaks andmetöötlemise seaduslikkust ning õigus esitada kaebus järelevalveasutusele, on täpsemalt kirjeldatud:

Privaatsuspõhimõtted Elektrooniliste teenuste osutamise reeglid-

Facebook Pixel

Turundusteenused

Teenuse kirjeldus

See on jälgimistehnoloogia, mida pakub Facebook ja mida kasutavad teised Facebooki teenused nagu näiteks Facebook Custom Audiences.

Töötlemisüksus

Facebook Ireland Limited

4 Grand Canal Square, Grand Canal Harbour, Dublin, D02, IirimaaAndmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Facebooki funktsioonide integreerimine

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

European Union

Polska

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

Artikkel 6(1) (1)(a) GDPR

-

Google Tag Manager

Analüüsiteenused

Teenuse kirjeldus

See on märgendihalduse süsteem. Kasutaja saab värskendada mõõtmiskoode ja vastavaid koodiosi – mille koondnimetus on märgendid – kas oma veebilehel või mobiilirakenduses.

Töötlemisüksus

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Iirimaa

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://policies.google.com/privacy?hl=en

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Clickmeeting

Vajalikud teenused

Teenuse kirjeldus

Teenus, mida kasutatakse veebikohtumste ja reaalaja veebiseminaride korraldamiseks.

Töötlemisüksus

ClickMeeting sp. z o.o.; Gdańsk, Poola

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://clickmeeting.com/pl/legal

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Freshmail

Vajalikud teenused

Teenuse kirjeldus

Selle veebilehe kaudu pakutakse e-posti turundusteenuseid.

Töötlemisüksus

FreshMail Holding S.A.; Kraków, Poola

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://freshmail.com/privacy-policy-2/

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Ads

Analüüsiteenused

Teenuse kirjeldus

Reklaamiteenuste pakkuja.

Töötlemisüksus

Google Ireland Limited Google Building Gordon House, 4 Barrow Street, Dublin D04 E5W5, Iirimaa

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://policies.google.com/privacy?hl=en

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Ads Conversion Tracking

Analüüsiteenused

Teenuse kirjeldus

Reklaamiga kokkupuute tulemuste jälgimise teenus.

Töötlemisüksus

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Iirimaa

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://policies.google.com/privacy?hl=en

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

SmartLook

Analüüsiteenused

Teenuse kirjeldus

Töötlemisüksus

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

-

YouTube Video

Vajalikud teenused

Teenuse kirjeldus

Töötlemisüksus

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

-

Facebook Social Plugins

Turundusteenused

Teenuse kirjeldus

See on Facebooki pistikprogramm, mis võimaldab integreerida Facebooki sisu kolmandate veebilehtedega.

Töötlemisüksus

Facebook Ireland Limited 4 Grand Canal Square, Grand Canal Harbour, Dublin, D02, Iirimaa

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://www.facebook.com/policies/cookies/

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

AddThis

Analüüsiteenused

Teenuse kirjeldus

Töötlemisüksus

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

-

Yandex Metrica

Analüüsiteenused

Teenuse kirjeldus

Töötlemisüksus

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

-

Google Maps

Analüüsiteenused

Teenuse kirjeldus

See on veebikaardistamise teenus.

Töötlemisüksus

Google Ireland Limited Gordon House, 4 Barrow St, Dublin 4, Iirimaa

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://policies.google.com/privacy?hl=en

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

Google Analytics

Analüüsiteenused

Teenuse kirjeldus

See on veebianalüütika teenus. See võimaldab kasutajal mõõta reklaamide investeeringutasuvust, samuti jälgida Flash‘i, video- ja sotsiaalmeedia lehekülgi ning rakendusi.

Töötlemisüksus

Google Ireland Limited, Google Building Gordon House, 4 Barrow St, Dublin, D04 E5W5, Iirimaa

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://policies.google.com/privacy?hl=en

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

GrafiteCMS

Vajalikud teenused

Teenuse kirjeldus

Võimas sõltumatu sisuhaldussüsteem Laravel‘i rakendustele.

Töötlemisüksus

Grafite Inc., 777 Waterloo St, Mount Forest, ON N0G 2L3, Kanada

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

https://opensource.org/licenses/MIT

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci

-

e-värbaja

Vajalikud teenused

Teenuse kirjeldus

Töötlemisüksus

eRecruitment Solutions sp. z o.o. Group Pracuj SA

Andmetöötluse eesmärgid

Loetelus on näha andmete kogumise ja töötlemise eesmärgid.

Töötlemisüksuse tehtav andmetöötlus

Allolev link annab teavet nende andmete kohta, mida kogutakse, kui just seda teenust kasutate. Need võivad olla sellised andmed nagu IP-aadress, andmete säilitamise aeg või teenust pakkuva ettevõtte andmed.

Kasutatud tehnoloogiad

Loetelus on näha kõik tehnoloogiad, mida see teenus kasutab, et andmeid koguda. Tüüpilised tehnoloogiad on küpsised ja pikslid, mis paigutatakse brauserisse.

Õiguslik alus

Allpool on loetletud andmetöötluseks vajalik õiguslik alus.

Artikkel 6(1) (1)(a) GDPR

Töötlemise asukoht

See on peamine asukoht, kus kogutud andmeid töödeldakse. Kui andmeid töödeldakse ka teistes riikides, antakse sellest kasutajale eraldi teada.

Kasulikku

Kasutustingimused, privaatsuspõhimõtted.

https://pl.test.kan-therm.com/p/polityka-ochrony-prywatnosci